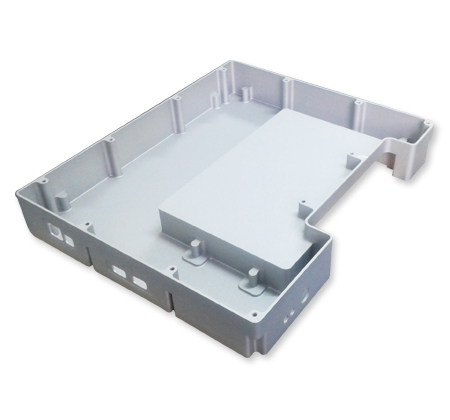

AXIS HOBBING AND 3-AXIS, 4-AXIS AND 5-AXIS MILLING

SIAF has a high-performance machine park with a range of strokes adapted to customer requirements and proven technical skills capable of easily handling 2-axis CNC turning as well as 3-axis, 4-axis and 5-axis CNC milling combined, if necessary, with angle gears to produce parts from the simplest to the most complex.

The manufacturing strategies offered by the CAM software are harnessed to optimise the cost and quality of the machined parts.

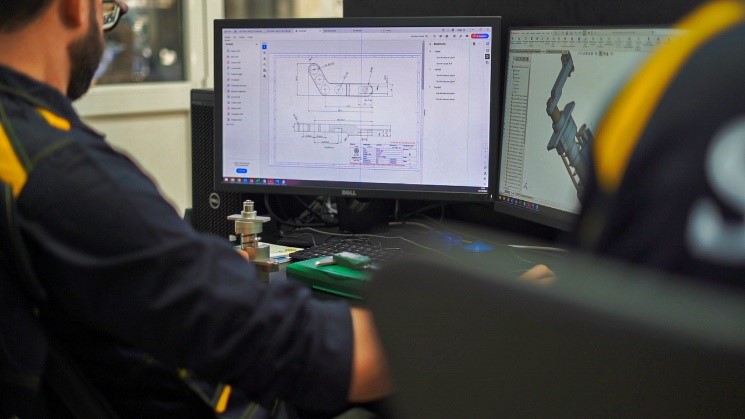

ENGINEERING OFFICE

SIAF has a design office whose mission is to provide you with optimised and customised solutions to your mechanical design needs.

We are well positioned on state-of-the-art products for sectors such as aeronautics, automotive, medical, food processing, etc.

PROCESS OFFICE

Home delivery

SIAF offers you a reliable and secure home delivery service throughout Tunisia. Receive your orders quickly thanks to an efficient logistics network. We work with trusted carriers to ensure each delivery. A simple and efficient way of getting your products to you.

quality control department

In precision mechanics, dimensional and geometrical tolerances must be respected. Based on this principle, SIAF has set up a highly equipped product quality control department. In addition to the usual inspection tools, a Three-dimensional Measuring Machine CMM is used to ensure the conformity of the machined products with extreme precision.

In addition to dimensional and geometrical inspection, the CMM is used for reverse engineering of undocumented customer parts in order to reproduce them with extreme precision.

ANODISATION SERVICE

SIAF specialises in colourless and coloured sulphuric anodising. In order to respond to the increased demands of customers, SIAF has set up an anodising unit equipped with :

- A test laboratory

- An anodising line of 14 anodising tubs with different dimensions.

Anodising has several advantages, such as:

- Increased corrosion resistance

- Improving resistance to chemical attack

- Thermal and electrical insulation

- The aesthetic and clean appearance of the anodised product.

SERVICE INTEGRATION OF ROBOTS

IN INDUSTRIAL PROCESSES

INDUSTRIAL DEVELOPMENT TAILORED TO YOUR NEEDS

Beyond an ideal price positioning, high performance and irreproachable machine precision, S.I.A.F. guarantees you an industrial development personalised to your needs and expectations.

S.I.A.F will provide you with a solution that will optimise your process, and is committed to working alongside you to :

- Produce at the lowest cost

- Optimise the quality of the manufactured product, make production more reliable, reduce the number of scrap parts and defects.

- Reduce operating costs, machine running time, warm-up time, commissioning time, energy consumption, consumables…

- Reduce the loss of human time, minimise maintenance and intervention costs

Our References

Ardia

Société SUD Industrie

draxlmaier

Galpharma

Philadelphia

Sotumeca

Safran

Stelia

Look cycle