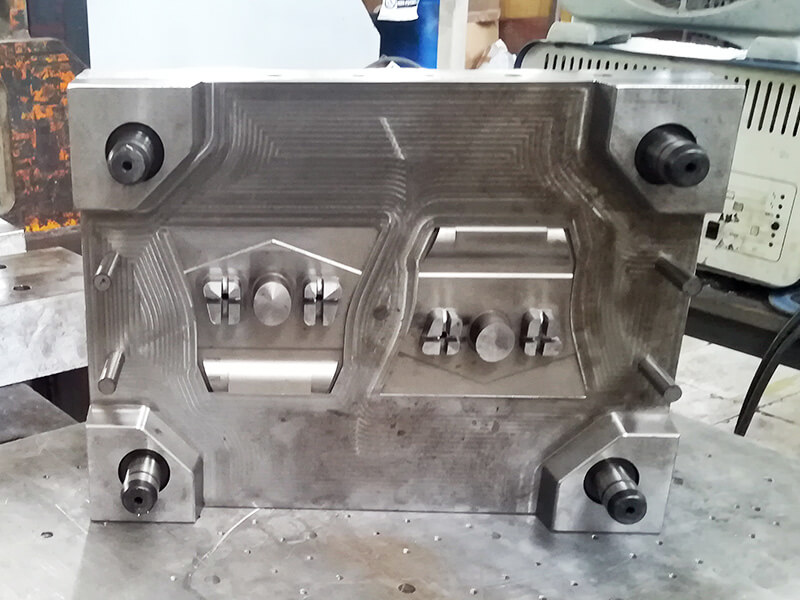

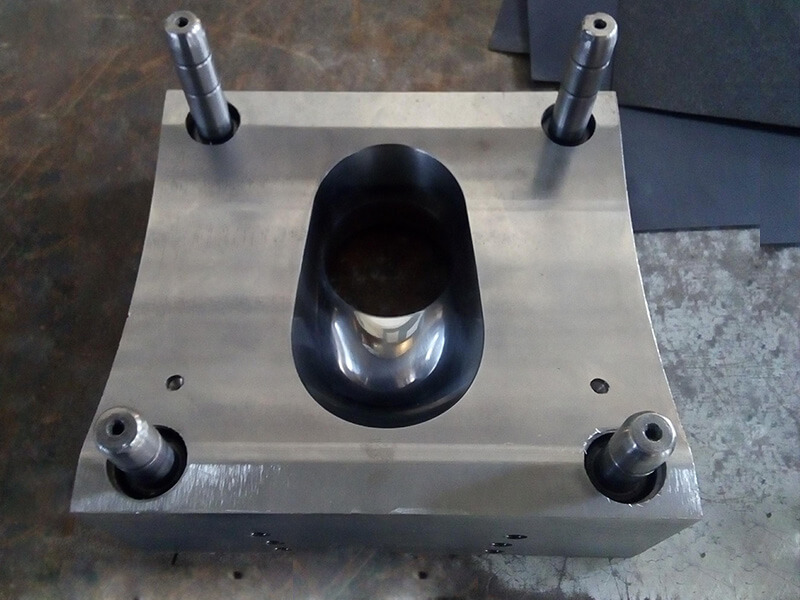

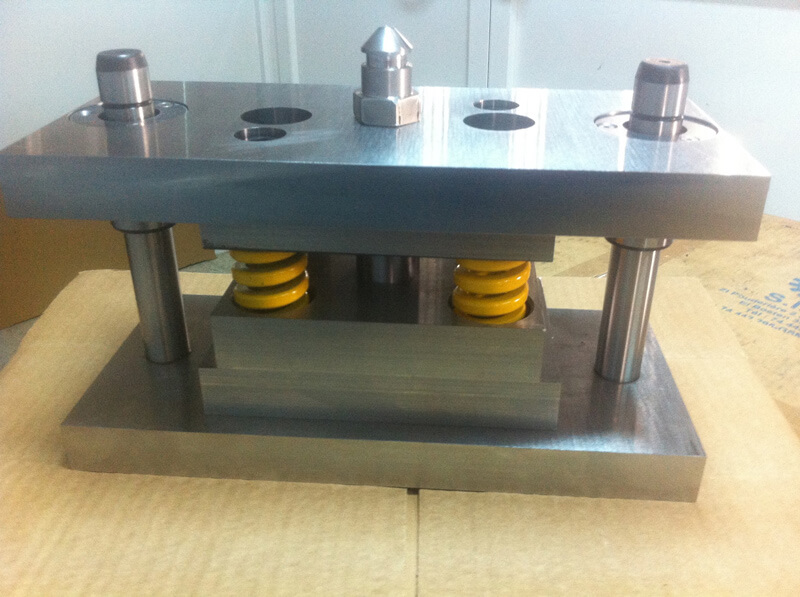

Design and manufacture of plastic injection moulds

Plastic injection is one of the processes best suited to the mass production of parts. This process uses the raw material in the form of either granules or powder..

This process makes it possible to obtain parts with complex geometries. Injection moulding involves softening (viscous state) the material and then kneading it at the plasticizing screw. It is then injected under high pressure. The molten polymer is injected under high pressure into a cold mould with one or more cavities. On contact with the cold walls, the material solidifies into shape and the object can then be removed from the mould.

SIAF offers complete services for the production of plastic injection tools and plasticising screws to meet the various needs of its customers.

Our achievements